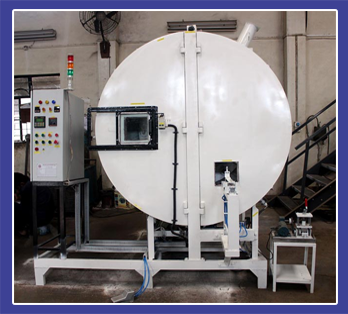

Index Type Trickle Impregnating Machine

Index Type Trickle Impregnating Machine, offered by us, is suitable for automatic impregnating of stators and rotors by trickle process. Our Index Type Trickle Impregnating Machine is rotated by a chain drive, which rotates the spindles mounted on indexing table at a speed suitable for trickling. Indexing Table is rotated by motor with gear box and limit or proximity switches. One can obtain Index Type Trickle Impregnating Machine from us at a very reasonable price.

Process Carried Out by the Machine :

« Job rotation system: Rotating spindles are mounted on the index table driven by electric motor, gearbox, chain and sprockets. An arrangement is provided such that when jobs come to loading - unloading station, spindles stop rotating for easy removal and placement.

« Heating system : Stators and Rotors are pre heated and cured while passing through the pre heating zone and post heating zone. Radiation type electric heaters do heating in pre-heating and curing zone with temperature control by Digital Temperature Indicating Controller with proportionate temperature control. Both the zones are insulated with glass wool to minimize heat loss. Both the zones are lined with reflective aluminum sheet backed by asbestos cloth for efficient heat reflection and distribution.

« Varnish feeding system : Varnish is fed by peristaltic tube pumps driven by D.C. motors with variable speed control to control varnish quantity according to the models. Pneumatic tube positioning system is provided for proper varnish feeding. Total cycle is automatic except for loading and unloading.

« Centralized control panel : is provided for complete pre-set automatic operation cycle except for loading and unloading. It is provided with cycle parameters settings such as pre-heating and curing temperature, varnish quantity, trickle time, total cycle time, etc. The PLC is provided to control the operation of the machine in proper sequence and safety.